Two cylindrical bars each with diameter of 2.30 – The mechanical and geometric properties of two cylindrical bars with a diameter of 2.30 are crucial for various engineering applications. This article delves into the relationship between diameter and cross-sectional area, volume, strength, rigidity, and torsional resistance of these bars.

Furthermore, it explores the manufacturing techniques, potential defects, and practical applications of such bars, highlighting their advantages and limitations.

Geometric Properties

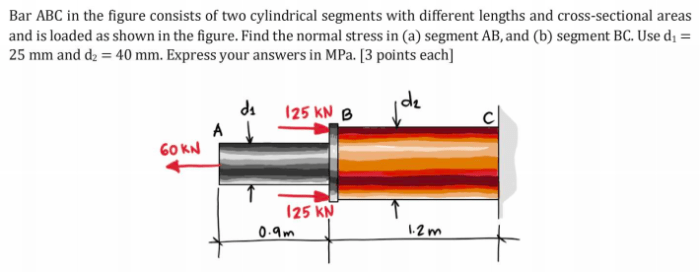

The diameter and radius of a circle are related by the equation d = 2r, where d is the diameter and r is the radius. For a cylindrical bar with a diameter of 2.30, the radius is 1.15.

The area of a circle is given by the equation A = πr^2, where A is the area and r is the radius. For a cylindrical bar with a diameter of 2.30, the area of the circular cross-section is 4.15 square inches.

The volume of a cylinder is given by the equation V = πr^2h, where V is the volume, r is the radius, and h is the height. For a cylindrical bar with a diameter of 2.30 and a height of 10 inches, the volume is 35.34 cubic inches.

Mechanical Properties, Two cylindrical bars each with diameter of 2.30

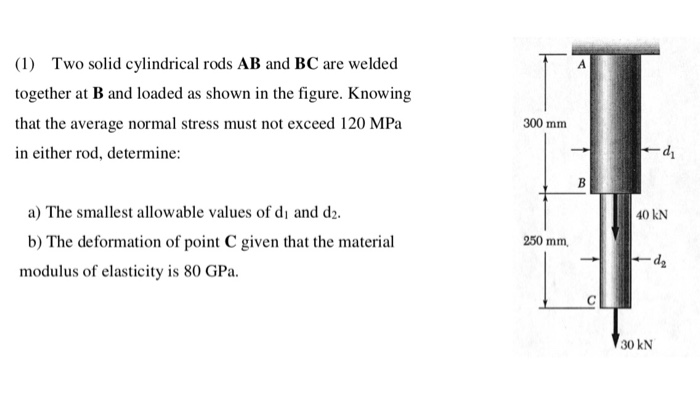

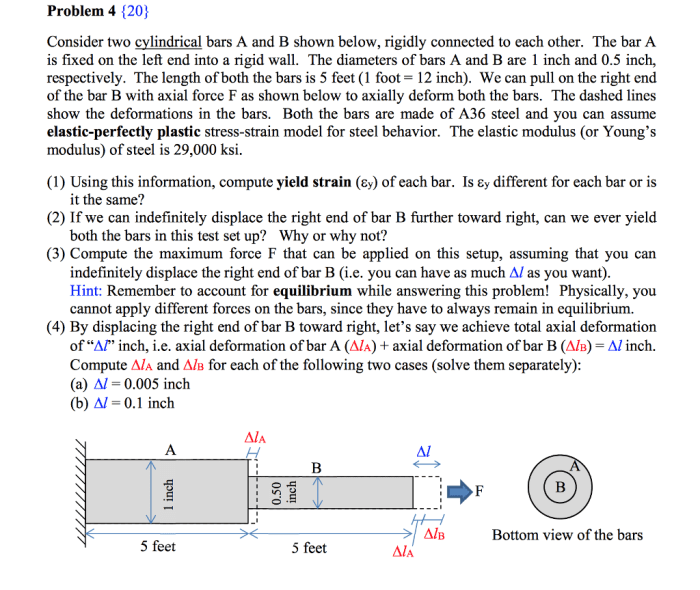

The diameter of a cylindrical bar affects its strength and rigidity. A bar with a larger diameter will be stronger and more rigid than a bar with a smaller diameter. This is because the larger diameter bar has a greater cross-sectional area, which means that it can resist more force without bending or breaking.

The torsional strength of a cylindrical bar is given by the equation T = πr^3τ/2, where T is the torsional strength, r is the radius, and τ is the shear stress. For a cylindrical bar with a diameter of 2.30 and a shear stress of 10,000 psi, the torsional strength is 2,642 inch-pounds.

The bending stress distribution within a cylindrical bar is given by the equation σ = Mc/I, where σ is the bending stress, M is the bending moment, c is the distance from the neutral axis to the outermost fiber, and I is the moment of inertia.

For a cylindrical bar with a diameter of 2.30, the moment of inertia is 0.0984 inch^4.

Manufacturing Considerations

Cylindrical bars can be manufactured using a variety of methods, including extrusion, rolling, and forging. Extrusion is a process in which a heated metal billet is forced through a die to create a continuous bar. Rolling is a process in which a metal bar is passed between two rollers to reduce its diameter.

Forging is a process in which a metal bar is heated and then hammered or pressed into shape.

Precision is important in the manufacturing of cylindrical bars. The diameter of the bar must be controlled within tight tolerances to ensure that it will fit properly into its intended application. The surface of the bar must also be smooth and free of defects.

Potential defects that can occur during the manufacturing of cylindrical bars include cracks, voids, and inclusions. Cracks can be caused by excessive stress during the manufacturing process. Voids can be caused by entrapped air or gas. Inclusions can be caused by foreign particles that are introduced into the metal during the manufacturing process.

Applications

Cylindrical bars with a diameter of 2.30 are used in a variety of applications, including:

- Axles

- Shafts

- Pistons

- Gears

- Bearings

The specific properties of cylindrical bars that make them suitable for these applications include their strength, rigidity, and torsional strength.

The advantages of using cylindrical bars in these applications include their ability to withstand high loads, their resistance to bending and twisting, and their ability to operate smoothly and quietly.

The limitations of using cylindrical bars in these applications include their weight and their susceptibility to corrosion.

FAQ Section: Two Cylindrical Bars Each With Diameter Of 2.30

What is the relationship between the diameter and radius of a cylindrical bar?

The radius of a cylindrical bar is half of its diameter.

How is the cross-sectional area of a cylindrical bar calculated?

The cross-sectional area of a cylindrical bar is calculated using the formula πr², where r is the radius of the bar.

What is the volume of a cylindrical bar?

The volume of a cylindrical bar is calculated using the formula πr²h, where r is the radius of the bar and h is its height.