Control valves used for water coils are typically the unsung heroes of efficient and reliable HVAC systems. These valves play a crucial role in regulating the flow of water through coils, ensuring optimal temperature control, flow regulation, and pressure relief.

In this comprehensive guide, we delve into the intricacies of control valves, exploring their types, selection criteria, sizing techniques, installation practices, and real-world applications.

Control Valves for Water Coils

Control valves play a crucial role in regulating the flow of water through water coils, ensuring optimal performance and efficiency in various applications. They are used to control the temperature, flow rate, and pressure of water, making them essential components in HVAC systems, industrial processes, and water distribution systems.

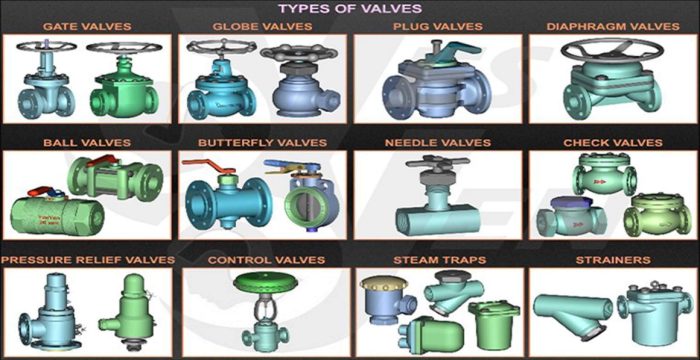

Types of Control Valves for Water Coils

Various types of control valves are used for water coils, each with its own advantages and disadvantages:

- Globe valves:Linear motion, high pressure drop, moderate flow capacity, require regular maintenance

- Butterfly valves:Rotary motion, low pressure drop, high flow capacity, less maintenance

- Ball valves:Rotary motion, high pressure drop, low flow capacity, easy to operate and maintain

- Gate valves:Linear motion, low pressure drop, high flow capacity, require occasional maintenance

Selection Considerations for Control Valves

When selecting a control valve for a water coil application, several key factors should be considered:

- System flow rate and pressure requirements

- Valve size and pressure drop

- Valve material compatibility with the fluid

- Controllability and accuracy

Control Valve Sizing and Performance: Control Valves Used For Water Coils Are Typically

Control valves for water coils are sized using Cv and Kv calculations, which determine the valve’s flow capacity.

Different flow characteristics of control valves, such as linear, equal percentage, and parabolic, impact system performance by affecting the flow rate at different valve openings.

Control Valve Installation and Maintenance

Proper installation and maintenance of control valves are essential for optimal performance:

- Valve mounting orientation should be as per manufacturer’s specifications

- Piping connections and support should ensure proper flow and prevent damage

- Regular inspection and servicing, including cleaning, lubrication, and testing, extend valve life and reliability

Applications of Control Valves in Water Coils

Control valves find applications in various systems involving water coils:

- Temperature control in HVAC systems:Regulating water flow to control the temperature of air

- Flow regulation in industrial processes:Controlling the flow of water used in cooling or heating processes

- Pressure relief in water distribution systems:Preventing excessive pressure build-up and protecting equipment

Expert Answers

What are the primary types of control valves used in water coils?

Globe valves, butterfly valves, ball valves, and gate valves are commonly employed in water coil applications.

How are control valves sized for water coils?

Cv and Kv calculations are used to determine the appropriate valve size based on flow rate and pressure drop requirements.

What factors influence the selection of a control valve for a water coil?

System flow rate, pressure requirements, valve size, pressure drop, material compatibility, and controllability are key considerations.